«Our strong commitment to the railway and electromobility sectors have enabled us to weather the impact of the crisis».

15/10/2020

15/10/2020

Avoiding the impact of COVID and its collateral damage to the economy and society has seemed an impossible task for the vast majority of companies. Despite this, many associates of the Federación de Empresarios del Metal (Metalworkers’ Federation) have been able to overcome the difficulties created by Coronavirus. Seville company, Hispacold International, which produces air conditioning units and equipment for buses, coaches and trains, is just such a case.

Roberto Recuerda Hernández, managing director of Hispacold International

FEDEME: 2019 was a year of enormous growth for your company but how are you tackling the challenges of the global crisis created by COVID-19?

R.R.: 2019 was the best year for growth in the history of Hispacold. Our company had a turnover of E47.7 million – an increase of 20% on the previous year. 2020 was predicted to be another growth year: we expected turnover to grow by a further 10%. Covid had an immediate and serious impact on the passenger transport sector and therefore on our business which is directly linked to the sector.

Although the impact of Covid on the purchase of new vehicles and fleets has differed, depending on whether we are dealing with the private or public sector markets, at the moment, public sector contracts are less affected than those in the private sector, and the rail industry has suffered less than the bus and coach markets.

In the first stages of the pandemic, there was a lot of economic uncertainty where our sector was concerned, as well as the social impact on society as a whole.

On the one hand, we had to roll out a raft of measures within the company in order to adapt to the new situation and to ensure that staff were able to continue to do their jobs with the guarantee of a safe and healthy workplace environment. On the other hand, we were affected by a stoppage in production for two weeks and had to revise downwards our yearly turnover in the light of forecasts from clients of smaller orders. Fortunately, we were not hit by cancellations of products already ordered but there was a fall-off in new orders in some segments.

We are certainly now used to working in an uncertain business climate and we monitor the evolution of our business much more closely.

It is also worth pointing out that a significant number of staff are continuing to work from home. Luckily, when the pandemic kicked in we were technologically prepared for homeworking and could continue our business activities without major disruption.

It is also fortunate that for several years, Hispacold had invested a lot of time and effort in the rail sector and in the electromobility markets and this strong commitment to these markets meant we had an order book for the next three years, which has cushioned us against a drop in orders from the bus and coach segment.

In fact, this year we can expect a 50% increase in business in the railway sector and ongoing growth in this segment in subsequent years. In any case, we should end the financial year with production running at levels similar to 2018.

FEDEME: What lines of business are you putting your efforts into as a way of exiting successfully from the situation caused by the pandemic.

R.R.: As we mentioned earlier, we are focusing heavily on the railway sector, on electric vehicles and on urban transport. We are also looking at thermal conditioning systems for vehicle components, not just passenger air conditioning, which will open up a very wide range of possibilities in the future.

We are also equally committed to marketing commercially our eCo3 air purifier. This is a device which was developed by the Technological Corporation of Andalucia, (CTA) in collaboration with Seville University 10 years ago and which has now taken on a special signifcance in the light of the pandemic because it guarantees good quality indoor air and prevents a build-up of pathogens. The eCo3 air purifier neutralizes pathogens, eliminates odors and prevents indoor air from becoming polluted while also increasing the concentration of oxygen.

Currently, around 10.000 of our eCo3 air purifier units are fitted in buses and coaches in more than 20 countries, while demand has risen dramatically due, logically, to concern among operators about ensuring the safest possible environment for passengers.

The eCo3 air purifier cleans, disinfects and purifies the air inside buses and coaches

FEDEME: You are continuing with your expansion plans, which you were promoting before the Covid crisis and you are keeping your workforce fully intact without having to resort to the ERTE furlough scheme. This is a real feat. What would you say were the key factors which enabled you to continue to operate so successfully.

R.R.: It is certainly true that Hispacold has made a great effort to maintain the full employment of its staff and pay the salaries of its 210-strong workforce without resorting to the ERTE furlough scheme. This is because, firstly, our financial position is very healthy but also it is because we brought in-house, jobs and work that we had previously outsourced in earlier years. Other reasons include implementing creative measures to recover the days not worked, a significant reduction in fixed costs, a good portfolio of orders instigated in previous years in the railway and electromobility segment, as well as significant demand for the eCo3 purifier.

FEDEME: Innovation forms part of the company’s DNA to such an extent that you have your own Research and Development centre at your El Pino Integrated Production facilities. Is it Innovate or Die?

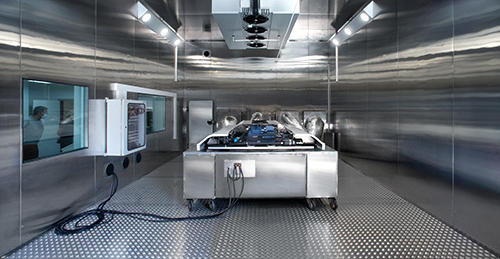

R.R.: We have just launched two thermal testing laboratories within our facilities so that we can test and validate the equipment in line with the increasingly demanding requirements of our customers. In all honesty, there are not many facilities like the one we have just opened in Andalusia.

From the start, Hispacold has kept the same philosophy: A commitment to innovation and to developing its own technology. Apart from the new products we are introducing to the market, we are continue to work on new, more environmentally friendly refrigerants, on new, quieter and continuous-flow, high-efficiency engines and on air treatment systems, etc.

New thermal and electrical testing laboratories at Hispacold

FEDEME: From Seville to the rest of the world…. in which international markets do you have a presence?

R.R.: Hispacold is committed to expanding its export markets and its foreign revenues are growing every year. Among our latest international projects, it is worth mentioning that we are supplying air conditioning systems in 200 city buses for the Moroccan city of Casablanca, air-conditioning units in 14 zero-emission buses (100% electric) for Genoa, Italy, and air-conditioning equipment in 50 electric buses for Paris and other French cities. We also have numerous double-decker electric bus projects in the UK, in collaboration with bus manufacturer, ADL.

In the railway sector, we have air-conditioning projects for regional trains in New South Wales (Australia), for trains running on London’s Dockland Light Railway (UK) and in Manila in the Philippines. We also have air- conditioning projects for the DMU (Diesel Multiple Unit) in Szeged (Hungary), for the Amsterdam, Naples and Quito undergrounds and for the streetcars in Jerusalem, Oslo, Basel, Lugano, Amsterdam, Birmingham, Augsburg and Mauritius, among others.

By the end of 2020, Hispacold will fit air-conditioning systems in 200 city buses running in Casablanca, Morocco

Proyecto: DIGIZITY - 0: INVESTIGACIÓN INDUSTRIAL DE SOLUCIONES INNOVADORAS PARA DESCARBONIZAR, DIGITALIZAR Y AUTOMATIZAR EL TRANSPORTE URBANO CON AUTOBUSES 0 EMISIONES

Acrónimo: DIGIZITY

Líder: AVANZA ZARAGOZA SAU

Socios participantes: AVANZA SPAIN, S.L., IDNEO TECHNOLOGIES, S.A., INTERNACIONAL HISPACOLD, S.A., IRIZAR, S.COOP., JEMA ENERGY, S.A. y TELNET REDES INTELIGENTES, S.A.

Organismos de Investigación: ITAINNOVA - Instituto Tecnológico de Aragón, Fundación TECNALIA Research & Innovation y CTAG - Centro Tecnolóxico de Automoción de Galicia.

Presupuesto total del proyecto: 9.094.670, 00€

Subvención otorgada: 5.440.703,35 €

Duración del proyecto: 01/11/2021 - 31/12/2023

Proyecto financiado por la Unión Europea - NextGenerationEU a través de la convocatoria para el año 2021 Programa Tecnológico de Automoción Sostenible, en el marco del Plan de Recuperación, Transformación y Resiliencia y del Programa Estatal para Catalizar la Innovación y el Liderazgo Empresarial del Plan Estatal de Investigación Científica, Técnica y de Innovación 2021-2023 promovido por el Centro para el Desarrollo Tecnológico e Industrial (CDTI)

Financiado por la Unión Europea - Next Generation EU

INTERNACIONAL HISPACOLD S.A ha participado en el proyecto tractor PERTE VEC CAPITAL (2022-2025), liderado por IRIZAR, bajo el marco del PERTE del Vehículo Eléctrico (PERTE VEC) publicado en el año 2021. Este proyecto ha sido financiado por el Ministerio de Industria, Comercio y Turismo, conforme al artículo 18 de la Ley 38/2003, de 17 de noviembre, General de Subvenciones. Además, INTERNACIONAL HISPACOLD S.A ha recibido apoyo financiero del Mecanismo de Recuperación y Resiliencia, y del Plan de Recuperación, Transformación y Resiliencia.